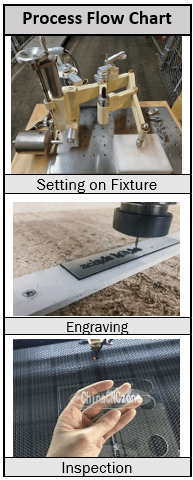

Engraving Costing Tool

1

Enter Part Information

2

View Estimate

3

Enable Customization (Opt.)

4

Unlock Global costs

5

Save

Engraving is a process where a design or text is incised or etched onto a surface using specialized tools, resulting in permanent and detailed markings. It is commonly used for personalization, artistic expression, and adding intricate details to custom materials like Marble and Granite, Stone and Brick, Acrylic, Cardboard, Paper, Fabric, Leather, metal, wood, glass, or plastic, etc. Our comprehensive engraving costing analysis and estimation tools provide valuable insights into pricing. Optimize your engraving costs with our cost calculator and effective cost management strategies. Explore factors influencing engraving costs and discover proven cost-saving techniques. Experience efficient engraving cost control and enhance your profitability in the engraving industry.

A) General Part Information

Unique Identification Number (UIN) Of Part:-

- Part Number which is usually mentioned on the drawing.(Alphanumeric values are accepted).

Part Description:-

- Part Name, Metal Pump, SS tank, Sheet container, etc. (Alphanumeric values are accepted).

B) Volume (Number of Pieces Produced)

Annual Volume:-

- The Number of Pieces that are Required in a Year. (Limit set for the tool : 1 - 10000000 Nos).

Lot Run Size:-

- The Number of Parts to be Processed in a Single Setup (Limit set for the tool : Less than or equal to Annual volume).

C) Material Type

Engraving On Base Material:-

- Select base material from the dropdown on which engraving is to be done.

D) Engraving Technology Parameters

Type of Engraving Equipment Technology:-

Select from the below two Technologies:-

1. ROTARY ENGRAVING - It is the process of using a spinning cutter in a motor-powered spindle to cut or rout into the material. ROTARY ENGRAVING is used when the volume is moderate and accuracy is low.

2. LASER ENGRAVING – It is the process of using lasers to engrave an object. laser engraving is used when the volume is high and accuracy is also high.

E) Part Characteristics