Injection Molding Costing Tool

1

Enter Part Information

2

View Estimate

3

Enable Customization (Opt.)

4

Unlock Premium Costs

5

Save

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure, allowing it to produce complex and precise plastic parts. Some commonly used Injection molding custom parts like jars, caps, containers, Automotive dashboards, bumpers, door panels, trim, and automotive lighting Bottles. Our advanced injection molding cost estimator, calculator, and cost model provide accurate pricing insights. With our comprehensive injection molding cost analysis, optimize your manufacturing expenses and gain control over production costs. Whether you need to calculate injection molding unit cost, part cost, or overall manufacturing cost, our specialized tools have got you covered. Analyse pricing strategies, compare injection molding costs, and enhance profitability with our efficient injection molding cost optimization solutions. Get precise insights into your injection molded part and product cost, ensuring competitive pricing and cost-effective manufacturing.

A) General Part Information

Part Number:-

- Part Number which is usually mentioned on the drawing. (Alphanumeric values are accepted).

Part Description:-

- Part Name, such as Front plastic desk, Mirror LH/RH, etc. (Alphanumeric values are accepted).

B) Volume (Number of Pieces Produced)

Annual Volume:-

- The Number of Pieces that are Required in a Year (Limit set for the tool: 1- 10000000 Nos).

Lot Run Size:-

- The Number of Parts to be Processed in a Single Setup (Limit set for the tool: Less than or equal to Annual volume).

C) Material Specific Information of Parts to be Manufactured

Select the material:-

-Select the material used to manufacture the Part from the dropdown list.

Select from drop down menu:-

-Select from the drop-down menu if the Part requires Colour Additive Required/Not required.

D) Part Specific Information

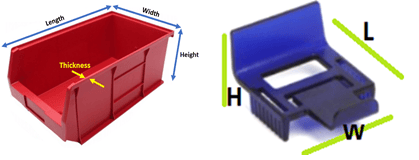

Part Max Length L (MILLIMETERS):-

- Enter Part Maximum Length dimension. (Limit set for the tool : 1 to 1200 mm)

Part Max Width W (MILLIMETERS):-

- Enter Part Maximum Width dimension. (Limit set for the tool : 1 to 1200 mm)

Part Max Height H (MILLIMETERS):-

- Enter Part Maximum Height dimension. (Limit set for the tool : 1 to 200 mm)

Average Wall Thickness (MILLIMETERS):-

- Enter Part Average Wall Thickness. (Limit set for the tool : 1 to 10 mm)

Part Weight (Grams):-

- Enter Part weight in Grams. (Limit set for the tool : 5 to 2000 grams)

E) Special Part Characteristics

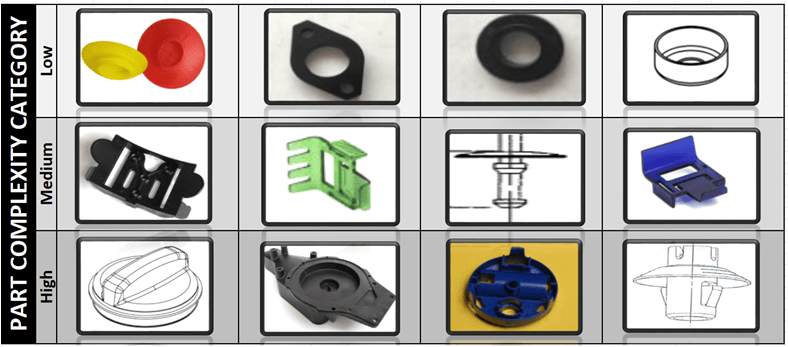

Complexity of the shape of the part:-

- Select from dropdown – (Low, Medium, Complex)

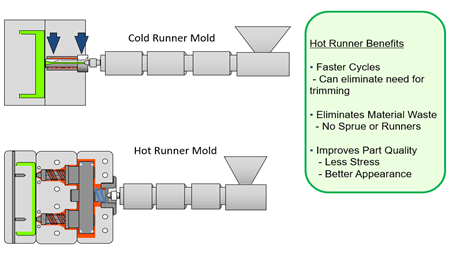

F) Molding Technology Selection

Select If Using Hot or Cold Runner Tooling:-

- Select If Using Hot or Cold Runner Tooling

G) Generic Secondary Processing