1

Enter Part Information

2

View Estimate

3

Enable Customization (Opt.)

4

Unlock Global costs

5

Save

Plastic Welding Costing Tool

Plastic Welding is a process of joining plastic components through the application of heat or pressure, creating a strong and permanent bond. Widely used in industries such as automotive and manufacturing, etc. Plastic welding can be done on custom parts like hood components, automotive interior trim components, medical filtration devices, consumer appliance components, and other car interior components, etc. Plastic welding costing analysis involves a comprehensive assessment of the welding process to identify cost drivers and areas for improvement. By analyzing factors such as material consumption, labor, equipment, energy usage, and overhead expenses, manufacturers can gain insights into the cost structure of plastic welding projects. This analysis helps identify opportunities for cost reduction, process optimization, and resource allocation.

A) General Part Information

Part Number:-

- Part Number which is usually mentioned on the drawing.(Alphanumeric values are accepted).

Part Name:-

- Part Name, such as Front plastic desk, Mirror LH/RH, etc.(Alphanumeric values are accepted).

B) Volume (Number of Pieces Produced)

Annual Volume:-

- The Number of Pieces that are Required in a Year.(Limit set for the tool : 1- 10000000 Nos).

Lot Run Size:-

- The Number of Parts to be Processed in a Single Setup.(Limit set for the tool : Less than or equal to Annual volume)

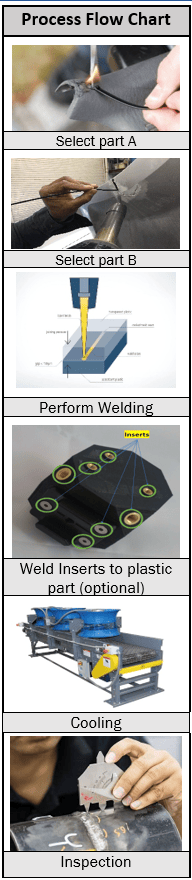

C) Material Specific Information of the Parts to be Welded.

Part A - Plastic Type:-

- Select the first plastic material which is going to be weld.

Part B - Plastic Type:-

- Select the second plastic material which is going to be weld.

D) Part Specific Information

Total Weight(Kg) - Part A + Part B:-

- Part A + Part B:- Sum of weights of all parts that would be welded together in the Process.

Thickness of Plastic (mm):-

- Enter the Maximum Thickness of the Part in the area where it is being Welded. (Limit set for the tool : 0.6 mm to 50 mm).

E) Welding Technology Section

Select Weld Type from dropdown

- For Laser weld need to add weld length.

F) Optional Hot Inserts