WHAT WE DO ?

- Our Cost Models

- Professional Staff

- Location

- CSC

- Our online cost-estimating tools support the following product types:

-

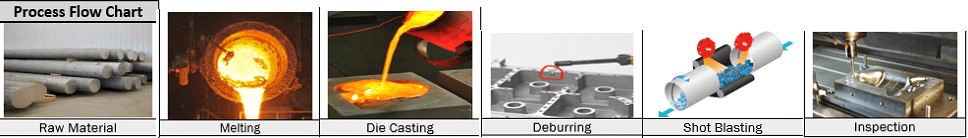

Our Cost Model tools explain each process flow according to the operations involved, as shown below:-

-

Our planned cost models for the future include the following:-

- At Costing Expert, we realize how important it is for businesses to know the manufacturing expenses to make educated decisions regarding sourcing, product development, and whether to create or buy items. As a result, we've spent years building and improving our cost model tools, which are based on over 2500 actual factory models built in partnership with factory management teams. Our models are supported by verified and audited material expenses, overhead costs, and equipment and plant floor operations, guaranteeing that you obtain a trustworthy estimate.

- We don't, however, depend solely on our cost model tools to offer you realistic estimates. Our degreed engineering staff is made up of manufacturing and costing professionals from all over the world, with expertise in a wide range of sectors. On staff are mechanical, chemical, electrical, industrial, operational, and manufacturing engineers, all of whom have a lot of expertise and information to draw from.

- We are based in the United States, but we have sites and cost engineering resources all around the world, including Europe, China, and India. We can give estimates for the key global manufacturing regions, including the United States, Mexico, China, India, Eastern and Western Europe, and Brazil, because of our global presence.

- Collaborative Supply Chains founded Costing Expert. Our clients rely on us to supply the knowledge they require to make sound decisions about their production processes.

-

Our Output section:

:-

-

Packaging cost Section:-

-

Volume Impact to Global Cost Section:-

-

Global Manufacturing Cost Section:-

-

Freight Cost Section:-

WHO ARE WE ?

- At Costing Expert, we specialize in a wide variety of manufacturing and cost-related services. From equipment selection and sizing to designing plant floor equipment cycle times and efficiencies, we have the expertise and experience to assist you in making informed decisions about your manufacturing operations.

- Our staff is adept at calculating equipment setup times, factory burden rates, and other overhead rates, as well as labor rates and the number of operators required for your production process. We can also help you develop SGA & (selling, general, and administrative) and profit margins.

- Our services are designed to assist you in optimizing your production processes and reducing costs while maintaining the high-quality standards that your customers demand. Our team is composed of degree engineers with expertise in mechanical, chemical, electrical, industrial, operational, and manufacturing engineering, and we have extensive experience in various industries.

- Effective communication is critical for any company's success, and at Costing Expert, we value open and honest communication with all of our clients, partners, and team members. We think that understanding our clients' goals and providing high-quality cost engineering and consulting services need clear and simple communication. We attempt to keep the lines of communication open, whether through in-person meetings, phone conversations, or email, to ensure that all parties involved are on the same page and working toward a single objective. We recognize that excellent communication is the basis of every successful project and are dedicated to keeping open lines of contact with all of our clients.

We are experts at the following:-

- Equipment Selection and Size

- Manufacturing Process Flow, Equipment Selection, and Size

- Development of Plant Floor Equipment Cycle Times and Efficiencies

- Development of Equipment Setup times

- Development Factory Burden Rate and Other Overhead Rates

- Development of Labor Rates and # of Operators

- Development of SGA and Profit % (selling general and administrative)

Visit our website to learn more and become a cost optimization champion!

Contact us Today!

Richard.Maroli@collaborativesupplychains.com

OUR COST MODELS

All over the world, we supply precise and dependable cost models. Our cost models are data-driven and fact-based, generated from over 2500 open-book costing models built for real-world industries worldwide. This provides us with a plethora of expertise and information from which to create cost models for our customers.

Our cost models are highly developed and built on a costing algorithm that assures the right application of cost drivers while also making them simple to use. This means you can rely on our cost models to be dependable and accurate, providing you with the data you need to make educated decisions about your production processes.

We can assist you whether you want to optimize your production processes, cut expenses, or just understand the cost of creating your products. Our degree engineering staff has experience in a range of sectors and is ready to collaborate with you to discover the best solutions for your production needs. Thank you for your interest in our firm. We look forward to assisting you in understanding the manufacturing costs of your items.

-

GLOBAL MANUFACTURING COSTING:-

We provide a complete cost model that accounts for the distinct economic elements of various places throughout the world. The United States, Mexico, Western Europe, Eastern Europe, China, India, and Brazil are all included. Our methodology considers the various material costs, labor rates, factory overhead rates, and plant floor operations in each location to ensure that our pricing is fair and accurate. We can offer our products and services at competitive pricing while keeping the highest level of quality by considering the individual demands and problems of each location.

-

RAW MATERIAL COSTS:-

To precisely assess the overall material use for our goods, we provide a rigorous raw material costing methodology. This comprises not just the end product's resources, but also frequent waste issues like gross material use vs actual part net weight and process trash. We also use freshly updated per-kilogram prices and add the cost of inbound freight to get the raw materials to our production to assure the most accurate pricing. We can offer low prices for our high-quality products while retaining a focus on efficiency and sustainability by taking all of these variables into account."

-

LABOR RATES AND COSTS:-

Our labor rates are adapted to each location of the world and consider a variety of elements to guarantee that our employees are compensated fairly and competitively. Wages, administration taxes, vacation and vacation compensation, healthcare benefits, and other considerations are among them. To guarantee that our price appropriately reflects the real cost of labor, we additionally evaluate the number of operators, breaks and lunches, and other process inefficiencies. We can offer our products and services at a competitive price while still supporting and appreciating our employees by considering all these elements.

-

FACTORY BURDEN RATES AND COSTS:-

Our factory burden rates are calculated to reflect the real cost of manufacturing in each region of the world. Depreciation, utilities, indirect labor such as maintenance, quality, material movement, shipping, and receiving, salaried management positions such as production supervision, quality manager, and plant management, building rent, repairs, and maintenance for both the building and equipment, software, warehousing, quality lab, and property taxes are all factors considered. We analyze the size and kind of production equipment, in addition to these expenditures, to guarantee that our prices are fair and competitive.

-

CYCLE TIMES AND EFFICIENCIES:-

Our factory burden rates are calculated to reflect the real cost of manufacturing in each region of the world. DeprOur cycle duration is meticulously calculated to account for all essential parameters such as component loading and unloading, manufacturing equipment size and speed, downtime, and operator breaks and lunches. We can properly anticipate the efficiency of our operations by taking these factors into account, which vary from 25% to 85% depending on the volume effect and process type. Furthermore, we are always reviewing and optimizing our cycle times to enhance efficiency and minimize costs..

-

PRIMARY EQUIPMENT SELECTION AND SIZE:-

We employ powerful algorithms to find the best type and amount of equipment for each operation, taking into consideration a variety of parameters such as the size and complexity of the pieces being produced. These algorithms also allow us to forecast the necessary cycle durations, set-up times, efficiencies, and number of workers required to efficiently run the equipment. Larger components, for example, will need larger production equipment and longer cycle durations.

-

SECONDARY MANUFACTURING PROCESSES:-

We provide cost models for a wide range of secondary manufacturing processes, including heat treatment, deburring, grinding, plating, coating, welding, engraving, component marking, and many more. These activities are frequently required for the manufacturing of high-quality components and products, and our cost models account for this by employing powerful algorithms to compute the cost of these processes. Furthermore, our cost models offer the same degree of depth and precision as our major production cost models, allowing consumers to easily comprehend and compare prices.

-

SET UP COSTS:-

Most industrial processes include some type of setup to get the equipment ready for production. Our cost models determine these fixed set-up costs automatically, using the formula (set up time in hours) x (labor rate per hour + burden rate per hour) and spreading them throughout the production lot run. The setup cost decreases as the lot run size grows because it is amortized over more pieces. We carefully analyze all important aspects when estimating set-up expenses to ensure accuracy and fairness.

-

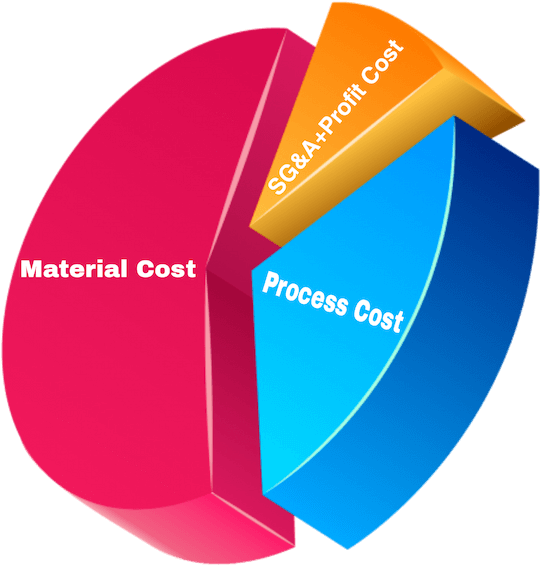

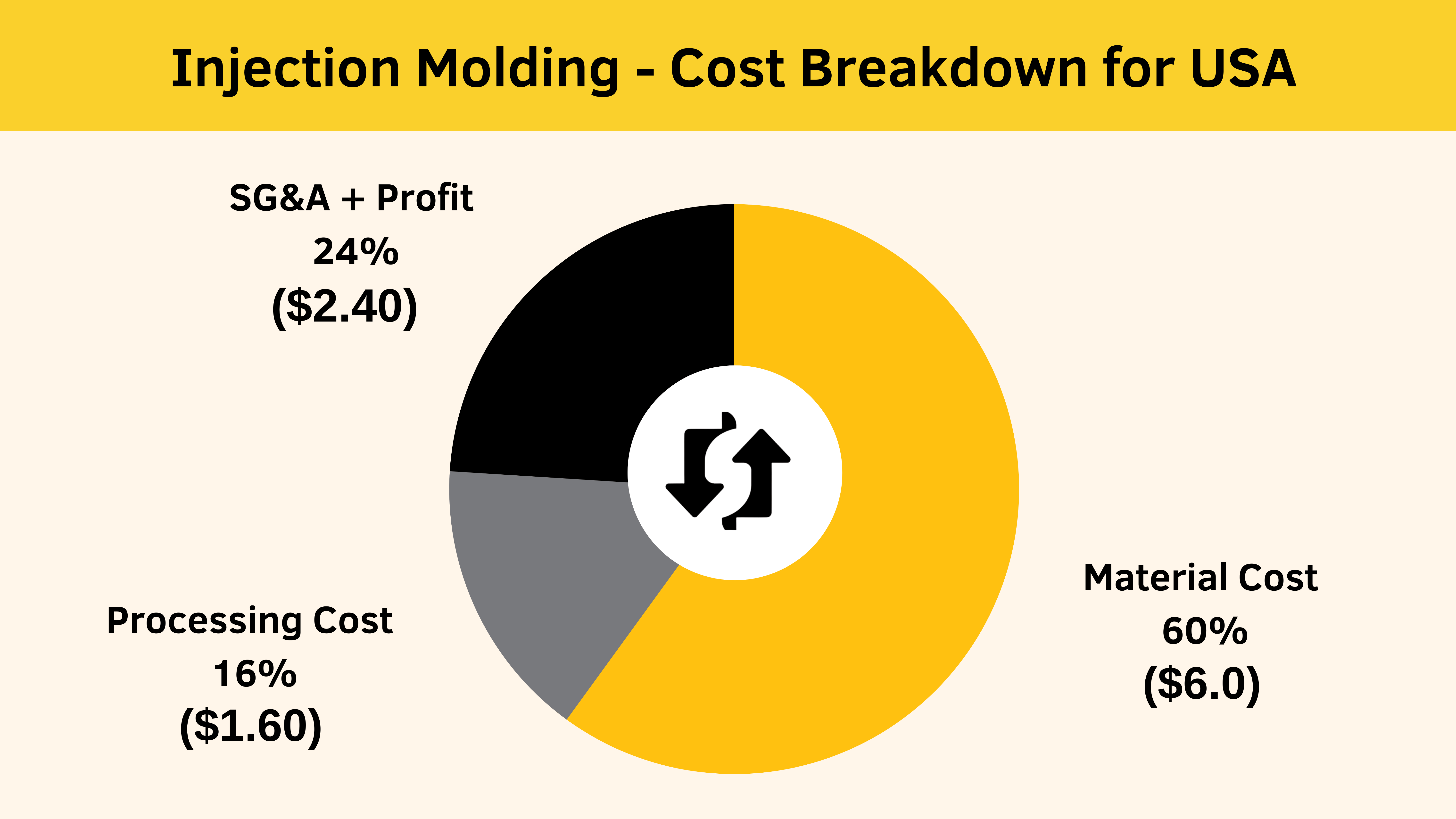

SG&A and PROFIT:-

SGA and profit costs, which include selling, general, and administrative expenditures, and profit, are often a substantial portion of the total cost of making a product. Sales and marketing, accounting and finance, executives, legal, engineering and product development, and profit are examples of these costs. The percentage of the selling price that these costs represent varies greatly depending on the industry and the volume produced. SGA and profit percentages tend to fall as volume grows owing to economies of scale.

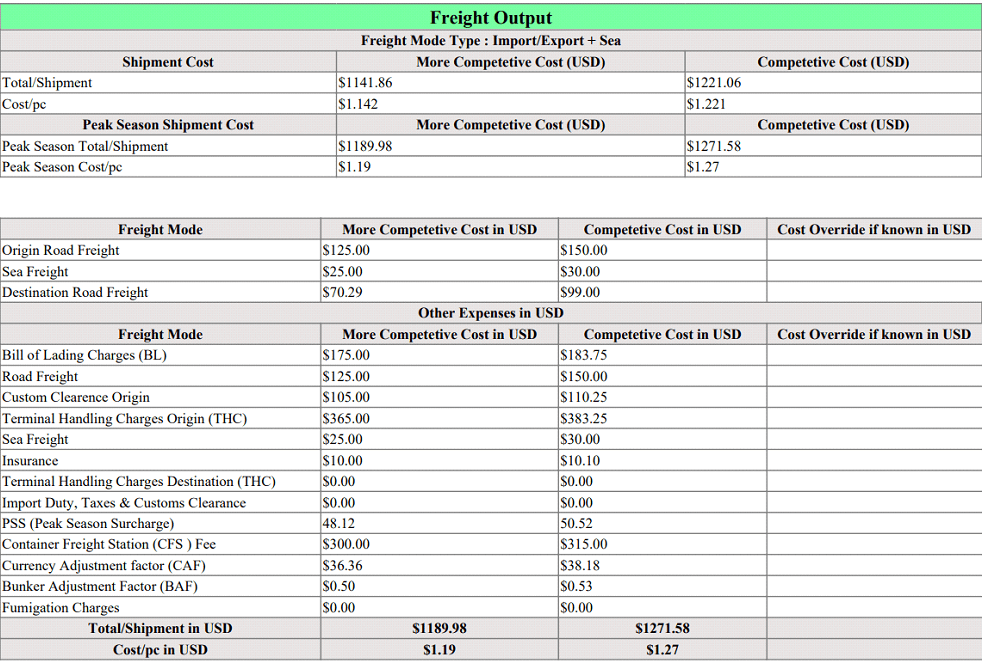

FREIGHT:-

Freight expenses are a significant component of the total cost of carrying items, whether they are carried locally or globally. Our freight cost calculations consider several elements, including method of transportation (road, sea, or air), distance traveled, and any applicable Incoterms, such as FOB and Ex-works. We also take into account any customs, levies, tariffs, or other administration fees that may apply to the shipment. We can assist our customers in making educated judgments regarding the most cost-effective transportation solutions by precisely assessing freight prices.

-

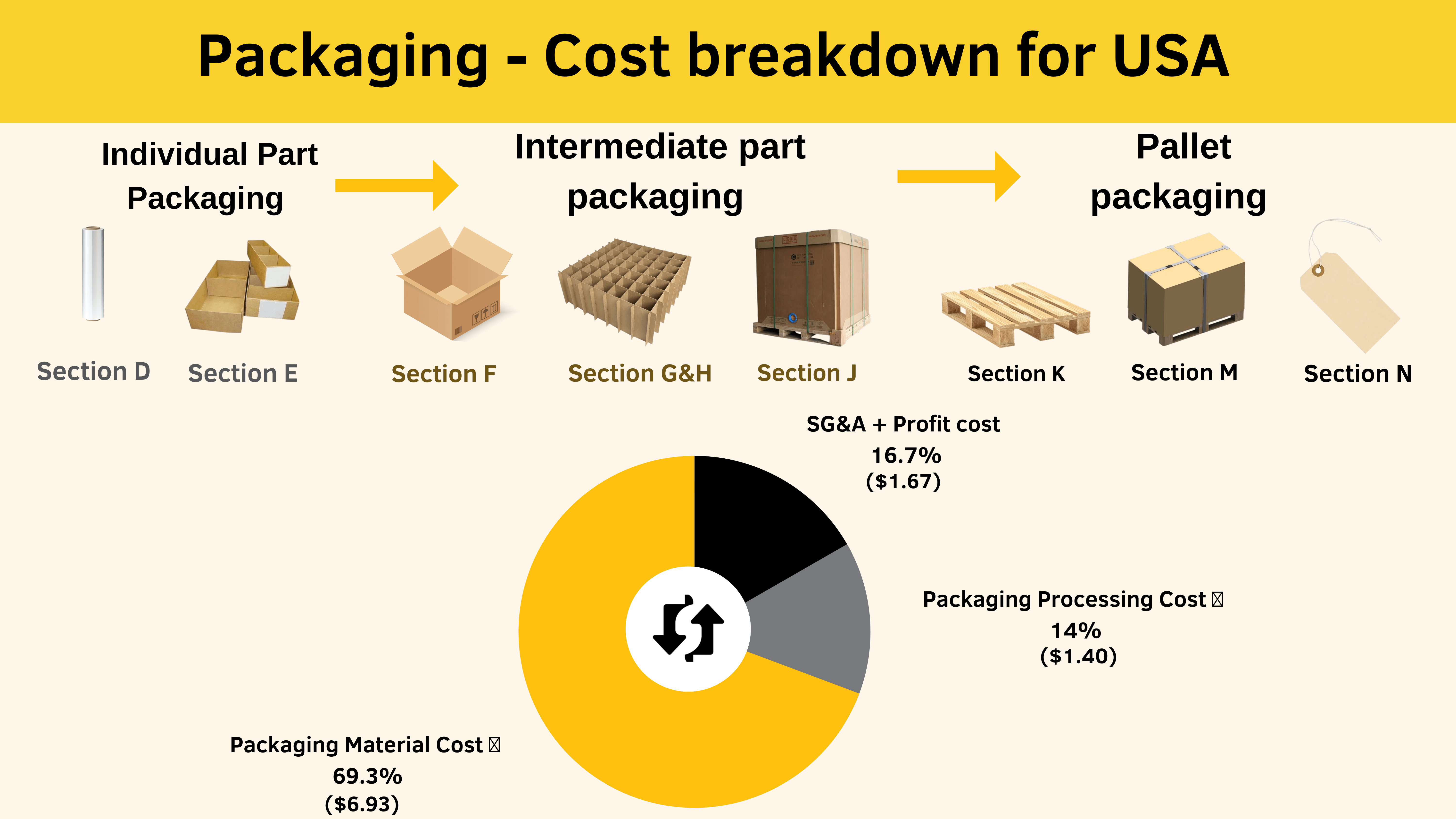

PACKAGING:-

Packaging is vital for many items because it protects the contents during transportation and handling. Our packaging expenses include the cost of packing materials such as pallets, boxes, bags, shrink wrap, and strapping, as well as the cost of applying the packaging on the parts. We can correctly assess the entire cost of packaging by taking both of these aspects into account. -

PRODUCTION LOT RUN SIZE:-

The several components produced in a single production run, which is normally planned monthly but can range from quarterly to yearly, are referred to as the production lot run size. The size of the production lot run can have a substantial influence on costs, especially when volumes are relatively low. We can deliver precise and dependable cost estimates to our clients by accounting for the manufacturing lot run size in our cost calculations.

-

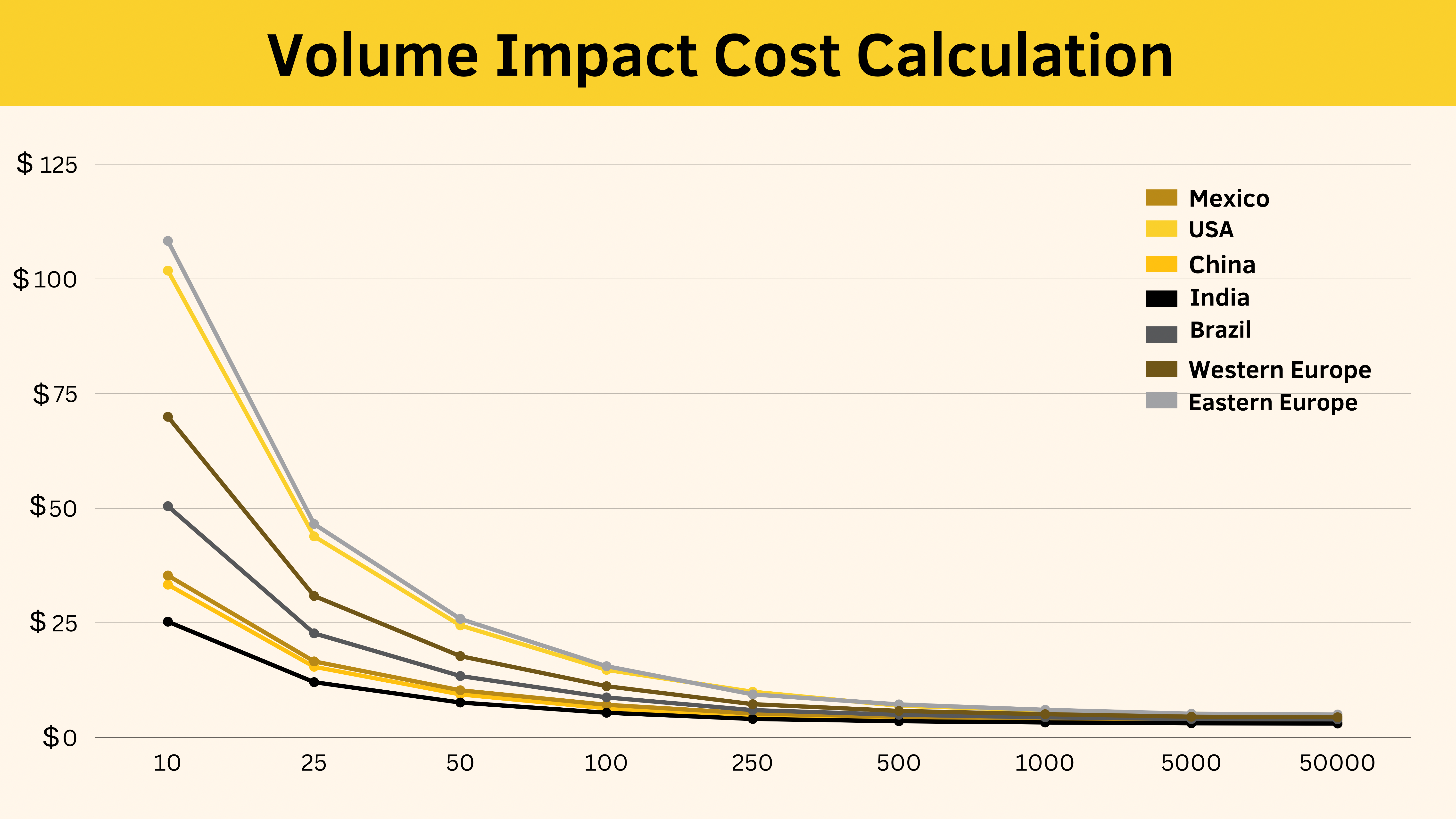

VOLUME IMPACT:-

Volume is an important component that might influence manufacturing costs, particularly when it comes to fixed-cost amortizations. Set-up expenses on a manufacturing line, for example, are deemed fixed and must be distributed (or amortized) throughout the entire lot run size. The fixed set-up expenses may be spread over greater volume as the lot run size grows, lowering the per-piece cost. Because of the lack of economies of scale, lower volumes often result in greater SGA and profit percentages. We can present a more accurate picture of the real cost of manufacturing at varied volumes to our clients by including volume in our cost estimates.

-

KEY ASSUMPTIONS & OVERRIDES:-

Our cost calculations include several significant assumptions and overrides that are intended to guarantee that our estimates are as accurate and dependable as possible. The type of process employed, the complexity of the products being produced, the efficiency of the manufacturing equipment, and the availability of raw materials and manpower are some of the major assumptions and overrides that we examine. We can give our clients a clear and thorough picture of the expenses involved in making their products by considering these elements.

-

ITEMS NOT INCLUDED IN OUR COSTING:-

A few elements are excluded from our costing estimates because they are regarded beyond the scope of our cost models. These expenditures might include research & development, product testing and certification, regulatory compliance, and other costs unrelated to the production process. We can offer a more accurate and trustworthy estimate of the real cost of manufacturing to our clients by clearly identifying these things and removing them from our cost estimates.

CONSULTING SERVICES:-

Powered by Collaborative Supply Chains

(Contact Email Richard.Maroli@costing-expert.com)

Collaborative Supply Chains is a cost engineering and consulting services company, aiding in supply chain management, product development and engineering, sales and quoting, and factory operations. Fortune 500 firms such as Lear, Adient, John Deere, Roush, CAT, Doosan, Bobcat, Flextronics, Sensata, Delphi, Aptiv, McDonald’s, Tate & Lyle, JBT, Filtran, Magna, Gates, Dayco are among our many delighted clients. We are committed to assisting our clients in optimizing their supply chains and reducing costs in all parts of their operations by using our knowledge and experience.

Regardless of whether you have drawings or CAD files, our cost model may be applied to any sort of part or assembly. We can cost parts based on photographs, pictures, representative parts, competitors’ parts, and even napkin designs. We can give precise product pricing for every case. Furthermore, our cost models are versatile and adaptive, allowing us to cost for significant global areas such as the United States, Mexico, Western Europe, Eastern Europe, China, India, and Brazil.

Whether you have drawings or CAD files accessible, our cost model may be used for any kind of item or assembly. We can cost items using photographs, photos, representative parts, rival parts, and even sketches made on a napkin. For every situation, we can give precise product costings. The flexibility and adaptability of our cost models also enable us to cost for the key geographical areas of the world, such as the United States, Mexico, Western Europe, Eastern Europe, China, India, and Brazil.

We can collaborate with you to create, evaluate, and roll out a cost model that is unique to your components, requirements, and supply chains. Understanding your needs is the first step in the process, which includes developing a prototype cost model, testing it, making any required adjustments, and assisting you in launching it. Additionally, we provide continuing assistance and training for changes to your cost model.

Our cost models are built to allow quick and precise costing, which will help you gain clients by offering quotations that are delivered quickly. We can assist you with reducing and standardizing expenses associated with BOM, tooling, engineering, product development, operations, assembly, packaging, and more. With reduced cost structures and improved sales and quotation efficiency, we want to help you succeed.

We provide aid with make vs. purchase analysis, benchmarking, and decision-making in addition to support for benchmarking internal processes. Our team can assist you in streamlining your processes to save costs and increase effectiveness since we have vast expertise in manufacturing and supply chain management.

We can assist you in locating vendors that can adhere to the goal costs established by our cost model. You may reduce costs and boost supply chain efficiency by choosing and working with the appropriate vendors. We know to find the greatest fit for your requirements and have a network of reliable partners.

You may find waste and savings in your supply chain with the aid of our cost engineering and cost modeling services. We can create and modify cost models that are tailored to your unique products, requirements, and supply chains so that you can use them to find current production efficiencies, establish goals for future production costs and prices, handle requests for price increases and offsets, and manage the cost creep associated with engineering changes. In addition, we may help with supplier inspections and audits, sophisticated buying support, and supplier searches.

TARGET USERS OF COST MODELING

SUPPLY CHAIN / PURCHASING COST SAVINGS IDENTIFICATION:- Costing Expert is a company that specializes in assisting supply chain managers and purchasers in understanding the actual cost of their products. We can proactively spot possibilities for waste reduction and cost reductions within the supply chain by using cost modeling methodologies, and we can engage with suppliers to make improvements. Our cost modeling procedures can also aid in creating a pipeline of cost-cutting options for bargaining, resource restructuring, and value engineering. With the ability to discover excessive pricing and waste in their supply chains as well as the most effective nations to purchase from, purchasing employees may become proactive rather than reactive. Additionally, this information may be used by buyers and purchasing managers to bargain better pricing with suppliers and raise the overall effectiveness of their supply chain.

ENGINEERING & PRODUCT DESIGN OPTIMIZATION:- As a business, we are aware of how critical precise cost data is for design engineers. Because of this, we provide cost modeling services that deliver thorough feedback quickly and based on facts. This makes it possible to compare design possibilities quickly and choose the most affordable choices. Our cost modeling procedures are a crucial tool for product designers, assisting them in making decisions and manufacturing-optimizing their ideas. This method sometimes referred to as design for manufacturing and design to cost, makes sure that things can be produced affordably without compromising on quality.

MAKE VS BUY:- Our cost modeling services at Costing Expert may be used to analyze competing manufacturing costs and pricing. To assist businesses, choose the most effective class of action and spot areas for development, this information may be compared to internal operations. Businesses may decide on the most cost-effective manufacturing approach by having a clear grasp of the real cost of production, whether it comes from internal resources or outside suppliers. Profitability and market competitiveness may increase as a result.

Industries Served

WHY REGISTER AS A USER?

You may benefit from a variety of useful services that can help you save time and money by registering with our page. You will be able to store all your cost estimates in your portfolio, which will make it simple to keep track of your costs and stay organized. Users will also be able to comprehend their expenses more precisely and thoroughly if they have access to premium costing alternatives like global manufacturing costing, freight cost estimations, and packaging cost estimations. Additionally, it will be simple for you to share your cost projections with other people if you need to. We also provide premium alternatives so you may get even more use out of your registration. Overall, there are a ton of benefits to joining our page; don't pass up the chance to take advantage of them all.

Become Register User

Already a member? Login

Companies that use cost models

Our Mission

Imagine you have the power and knowledge of what products should cost to manufacture? Now you can. Our cost models are easy to apply, providing detailed costing output that is highly customizable. In our user community, you are a COSTING EXPERT.